Sheet Metal Processing

SS Controls’ cabinet are being manufactured through CNC based setup involving high end Turret Punch, Fiber Laser and press brakes.

- Amada Turret Punch

- Mode : EMK 3612M-II

- Capacity : 30 Ton

- Processing length : 1.5m x 6m

- Processing Thickness : 6mm

- Amada Press Brake

- Model : HRB 2204

- Capacity : 220 Ton

- 7 Axes Machine

- Processing Length : 4m x thik 6mm

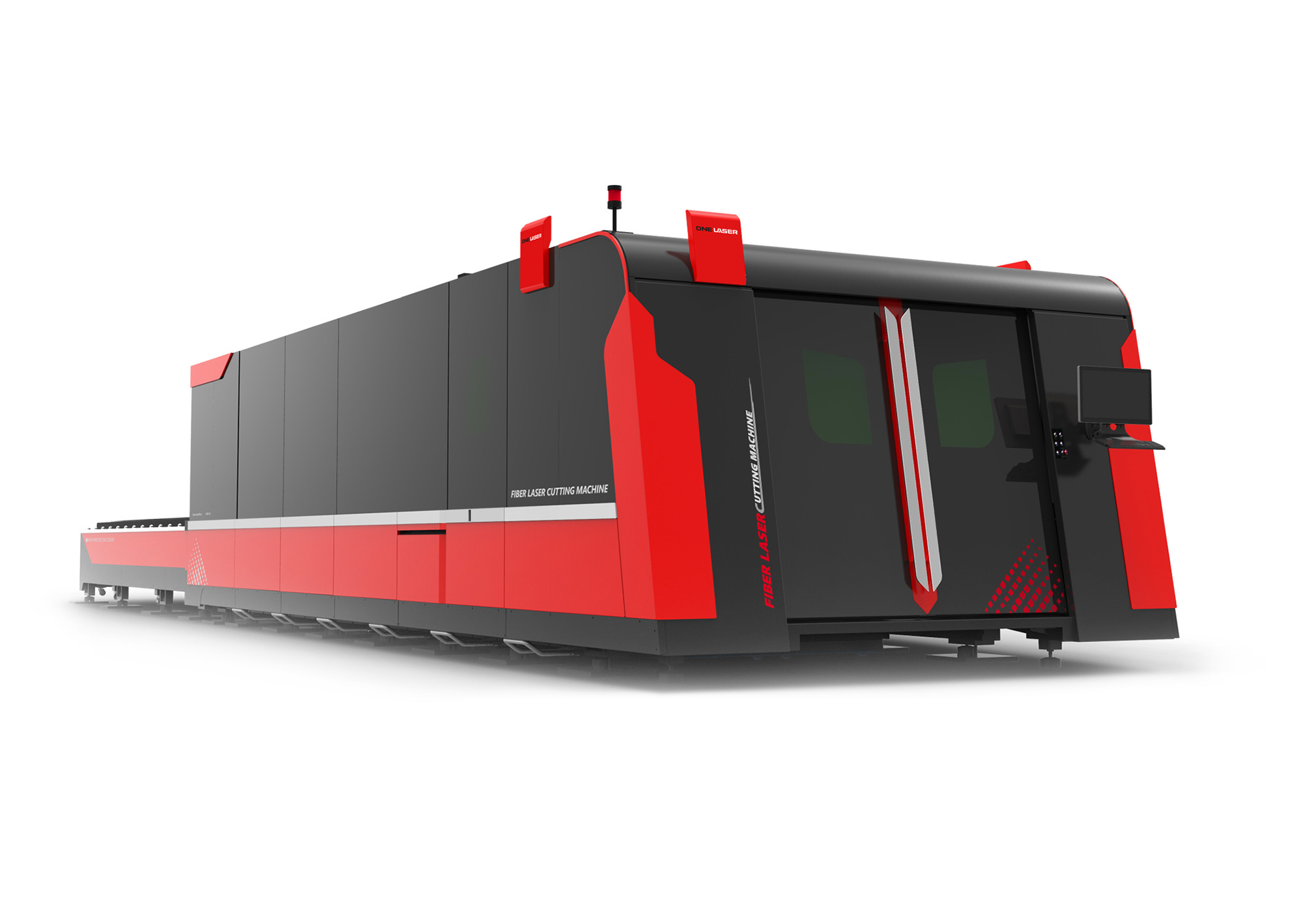

- DNE Bystronic Fiber Laser

- Model : Fiber Laser 3kW

- Bed Size : 2m x 4m